The introduction of vehicle programs featuring 100% electric propulsion has created new components and assemblies which are not found on vehicles featuring a traditional internal combustion engine (ICE) for movement. All of these new types of parts need to be shipped from the manufacturing plant to the assembly plant, just like all another vehicle parts have been transported throughout the history of automobile manufacturing. They also need to be safely stored in containers as work-in-process (WIP) before they are finished goods, and sometimes even held in custom containers while being moved through plant automation manufacturing systems.

Here is a short list and description of common BEV specific items for which Dunnage Engineering has designed and/or manufactured custom containers or dunnage components.

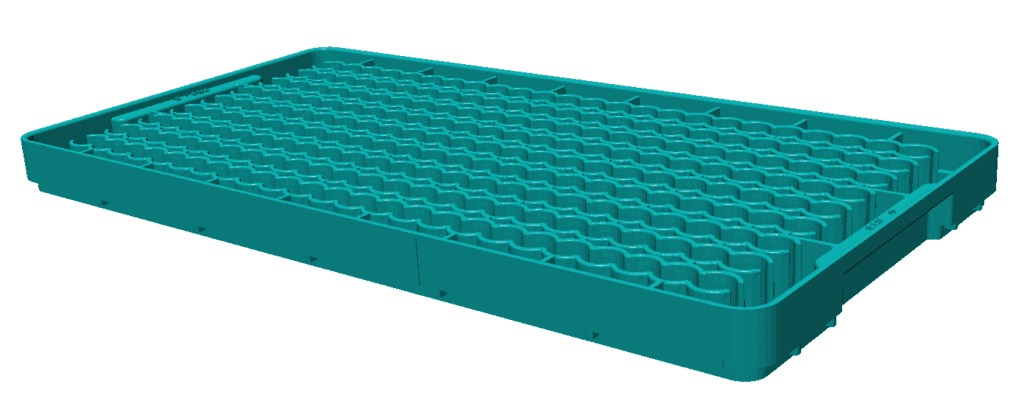

Battery cells

Stacking trays used in battery cell production and in-plant storage or shipping to battery module assembly facilities. They are designed to work with factory automation systems.

Electric drive units (EDU)

Custom designed cradles and supports secured into steel stacking racks for holding these electric motor assemblies during storage and transport to the vehicle assembly plant.

Battery module assemblies

Custom designed cradles and supports secured into steel stacking racks for holding these a complete finished battery assembly during storage and transport to the vehicle assembly plant.

Battery trays

Flipper tower assemblies or custom dunnage logs used in shipping racks which support the metal tray assembly in vehicle position assemblies during storage and transport to the vehicle assembly plant.

Battery top covers

Flipper tower assemblies used in shipping racks which support the part in horizontal orientation during storage and transport to the vehicle assembly plant.

Battery cooling modules

Custom designed cradles and supports secured into steel stacking racks for holding these modules during storage and transport to the vehicle assembly plant.

Battery cooling plate

Flipper tower assemblies or custom designed dunnage components secured into steel stacking racks for holding these parts during storage and transport to the vehicle assembly plant.

Battery cradles and supports

Custom designed dunnage components secured into steel stacking racks for holding these parts during storage and transport to the vehicle assembly plant.

Battery frames

Custom designed dunnage components secured into steel stacking racks for holding these parts during storage and transport to the battery module assembly facility.

Battery accommodating floor pan stampings

Flipper tower assemblies secured into steel stacking racks for holding these parts in horizontal orientation during storage and transport to the vehicle assembly plant.

We are happy to review any packaging requirements you have for upcoming BEV programs. We can propose various dunnage type and material solutions depending on the project requirements and projected volumes. We are happy to work with the vehicle manufacturer, part supplier or steel rack container supplier.