Vinyl Coated Steel

Vinyl Coated Steel

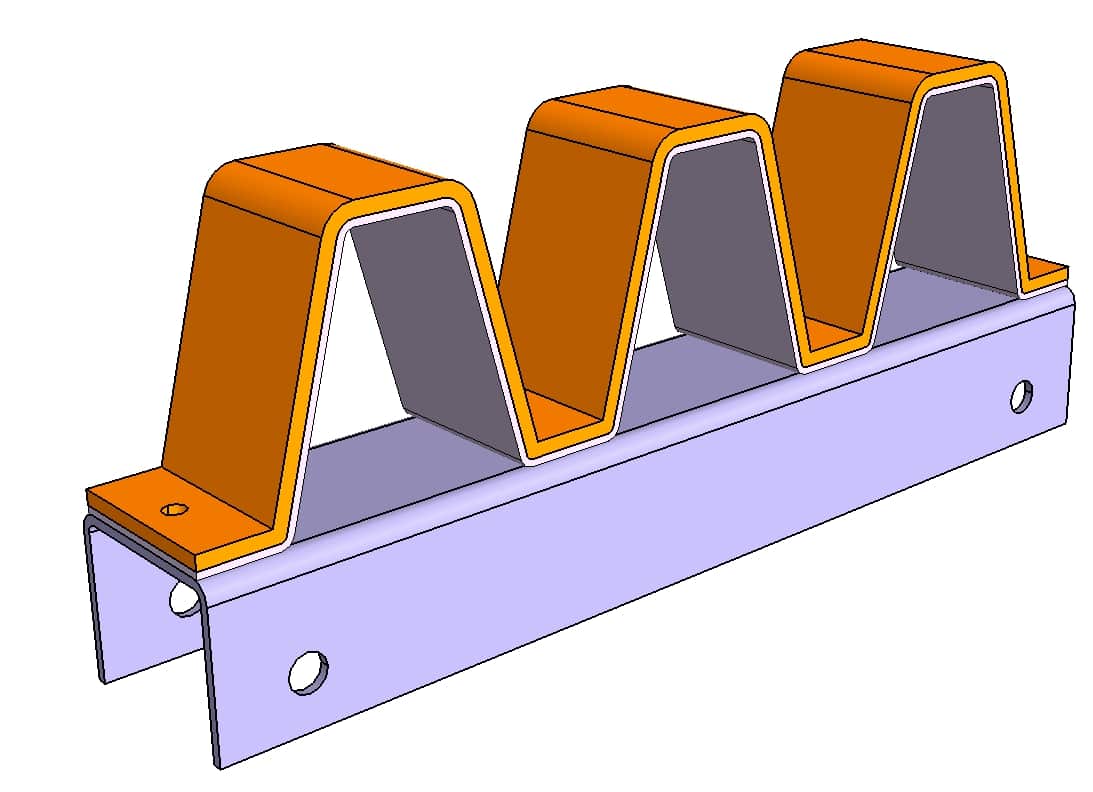

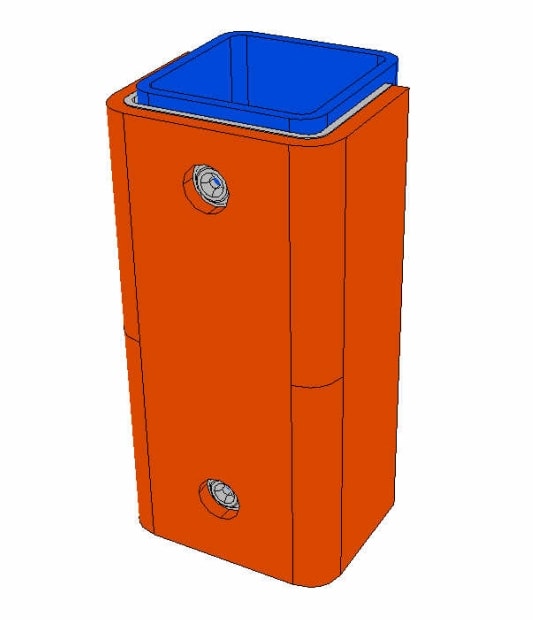

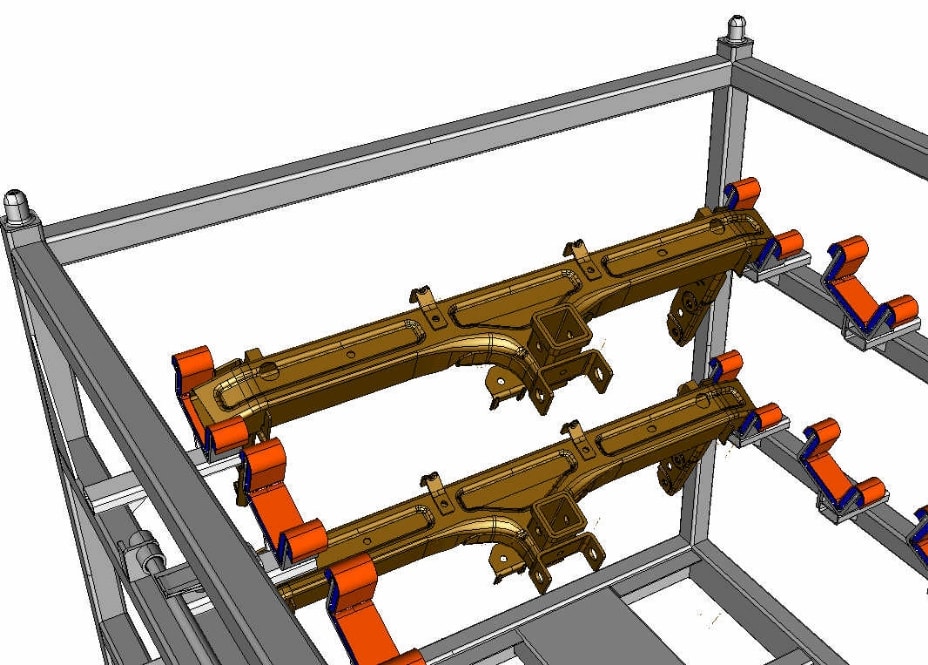

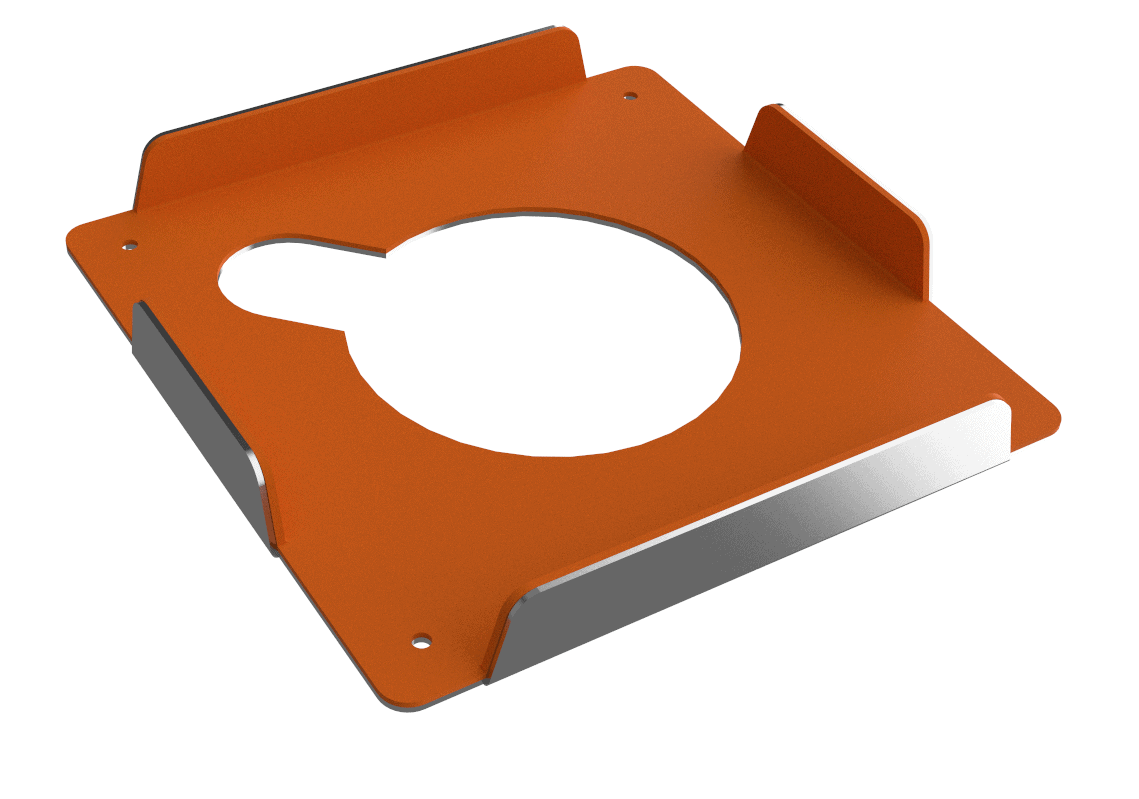

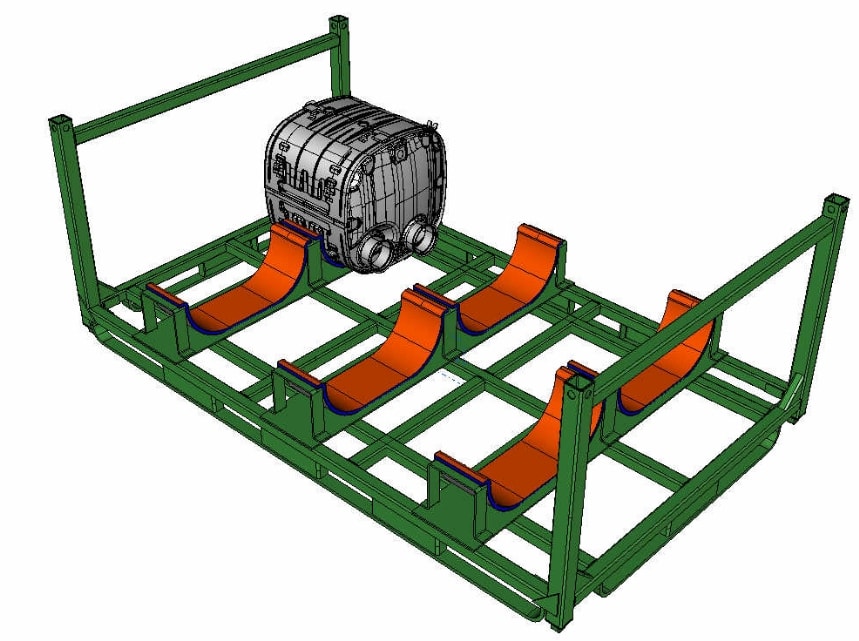

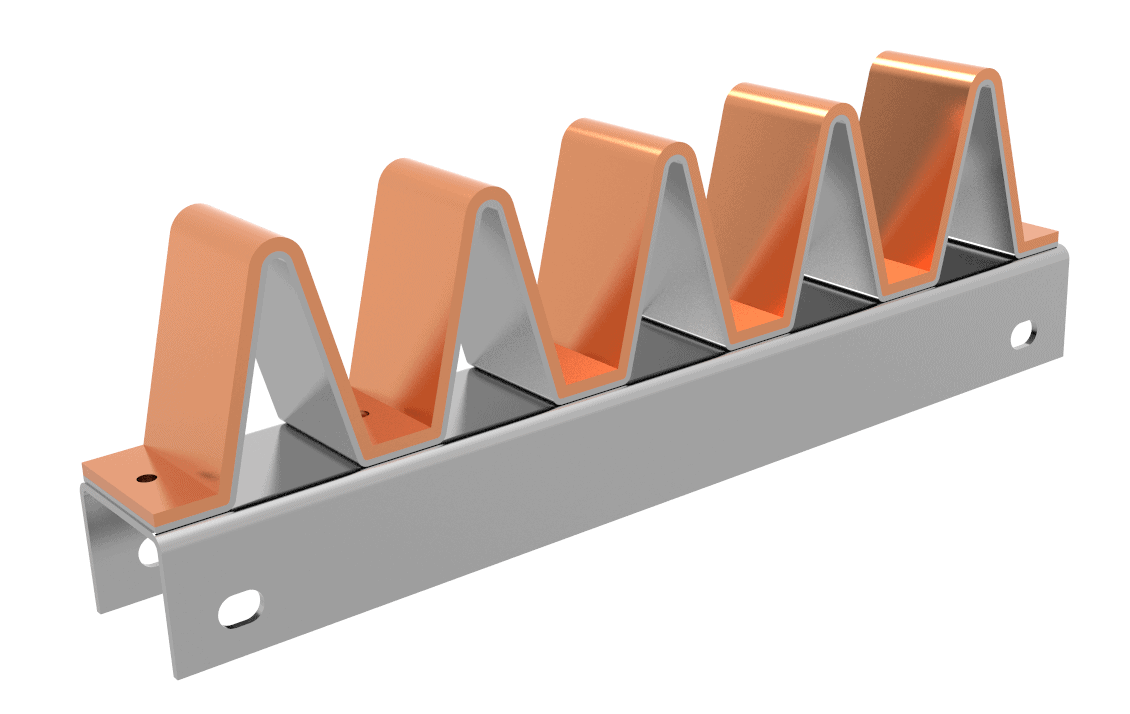

Invented by Dunnage Engineering back in 1961, Vinyl Coated Steel is used world-wide as a dunnage material for shipping containers. The vinyl coating is a tough cushioning material that is permanently bonded to rust-inhibiting galvanized steel and can be formed exactly to the contours of the part being held. The material holds its shape through years of repeated use to protect parts from damage during storage and shipment.

Vinyl Coated Steel can be formed into almost any shape without ever delaminating. Its design flexibility allows for a wide range of intricate dunnage shapes including deep draw, complex curves, angled pockets, and tight spacing. Dunnage Engineering manufactures Vinyl Coated Steel into fully fabricated dunnage components that are ready to be inserted into a shipping container.

Prototype samples can be developed very quickly and inexpensively. They are identical to actual production parts and therefore can be fully tested before manufacturing.

Material Options & Specifications

| Description | Coating Hardness | Steel Thickness | Overall Thickness |

||

|---|---|---|---|---|---|

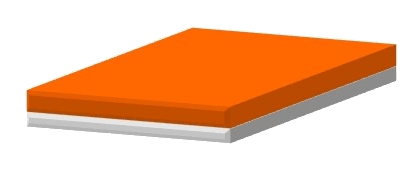

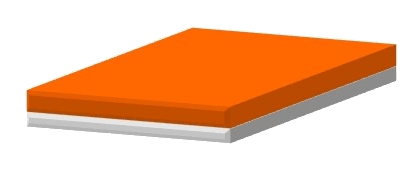

| Orange Vinyl |  | Durable vinyl laminated to galvanized steel. Offers good cut-resistance as well as cushioning. | 75 Shore A | 14ga, 12ga stock (2mm, 2.8mm) Others available | 0.25” stock (6mm) Others available |

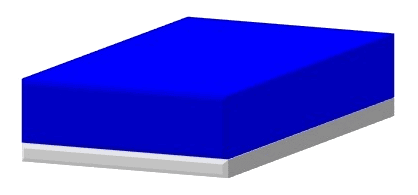

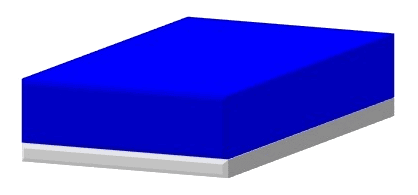

| Blue Foam |  | Semi-soft foam laminated to galvanized steel. Offers better cushioning properties. | 80 Shore “00” | 14ga, 12ga stock (2mm, 2.8mm) 10ga available (3.6mm) | 0.50” stock (13mm) Others available |

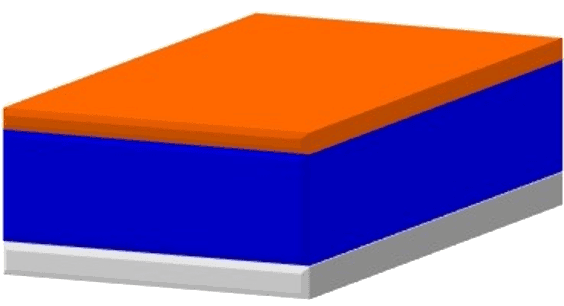

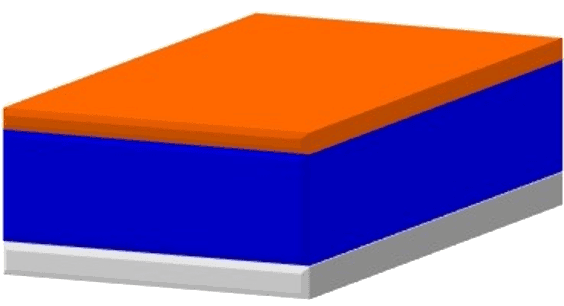

| Twincoat Vinyl |  | Blue foam laminated to galvanized steel with a layer of vinyl on top. Offers combination of cushioning and durability. | Combination* | 14ga, 12ga stock (2mm, 2.8mm) 10ga available (3.6mm) | 0.63” stock (16mm) Others available |

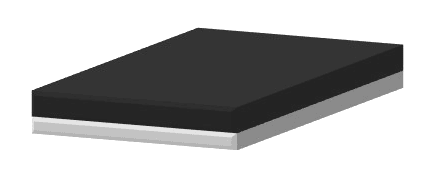

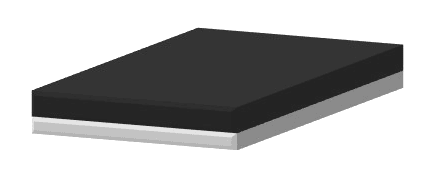

| Soft Black Vinyl (high COF) |  | Special order material offering tackier surface for applications that require a coating with more grip. Small amounts are occasionally in stock. | 60 Shore A | Typically 12ga (2.8mm) | Typically 0.25” (6mm) |

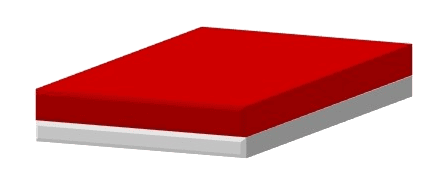

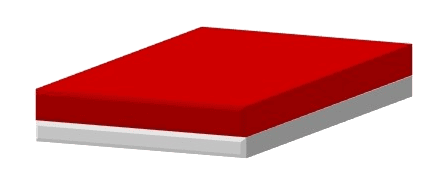

| Red Vinyl |  | Special order material with identical properties to standard Orange Vinyl but in special red color (PANTONE 186). Small amounts are occasionally in stock. | 75 Shore A | Typically 12ga (2.8mm) | Typically 0.25” (6mm) |

Material Options & Specifications

| Description | Coating Hardness | Steel Thickness | Overall Thickness |

||

|---|---|---|---|---|---|

| Orange Vinyl |  | Durable vinyl laminated to galvanized steel. Offers good cut-resistance as well as cushioning. | 75 Shore A | 14ga, 12ga stock (2mm, 2.8mm) Others available | 0.25” stock (6mm) Others available |

| Blue Foam |  | Semi-soft foam laminated to galvanized steel. Offers better cushioning properties. | 80 Shore “00” | 14ga, 12ga stock (2mm, 2.8mm) 10ga available (3.6mm) | 0.50” stock (13mm) Others available |

| Twincoat Vinyl |  | Blue foam laminated to galvanized steel with a layer of vinyl on top. Offers combination of cushioning and durability. | Combination* | 14ga, 12ga stock (2mm, 2.8mm) 10ga available (3.6mm) | 0.63” stock (16mm) Others available |

| Soft Black Vinyl (high COF) |  | Special order material offering tackier surface for applications that require a coating with more grip. Small amounts are occasionally in stock. | 60 Shore A | Typically 12ga (2.8mm) | Typically 0.25” (6mm) |

| Red Vinyl |  | Special order material with identical properties to standard Orange Vinyl but in special red color (PANTONE 186). Small amounts are occasionally in stock. | 75 Shore A | Typically 12ga (2.8mm) | Typically 0.25” (6mm) |

Application Examples

Get in Touch

See how we can meet your needs for returnable packaging and custom injection molding solutions.

Contact Us Request for Quote