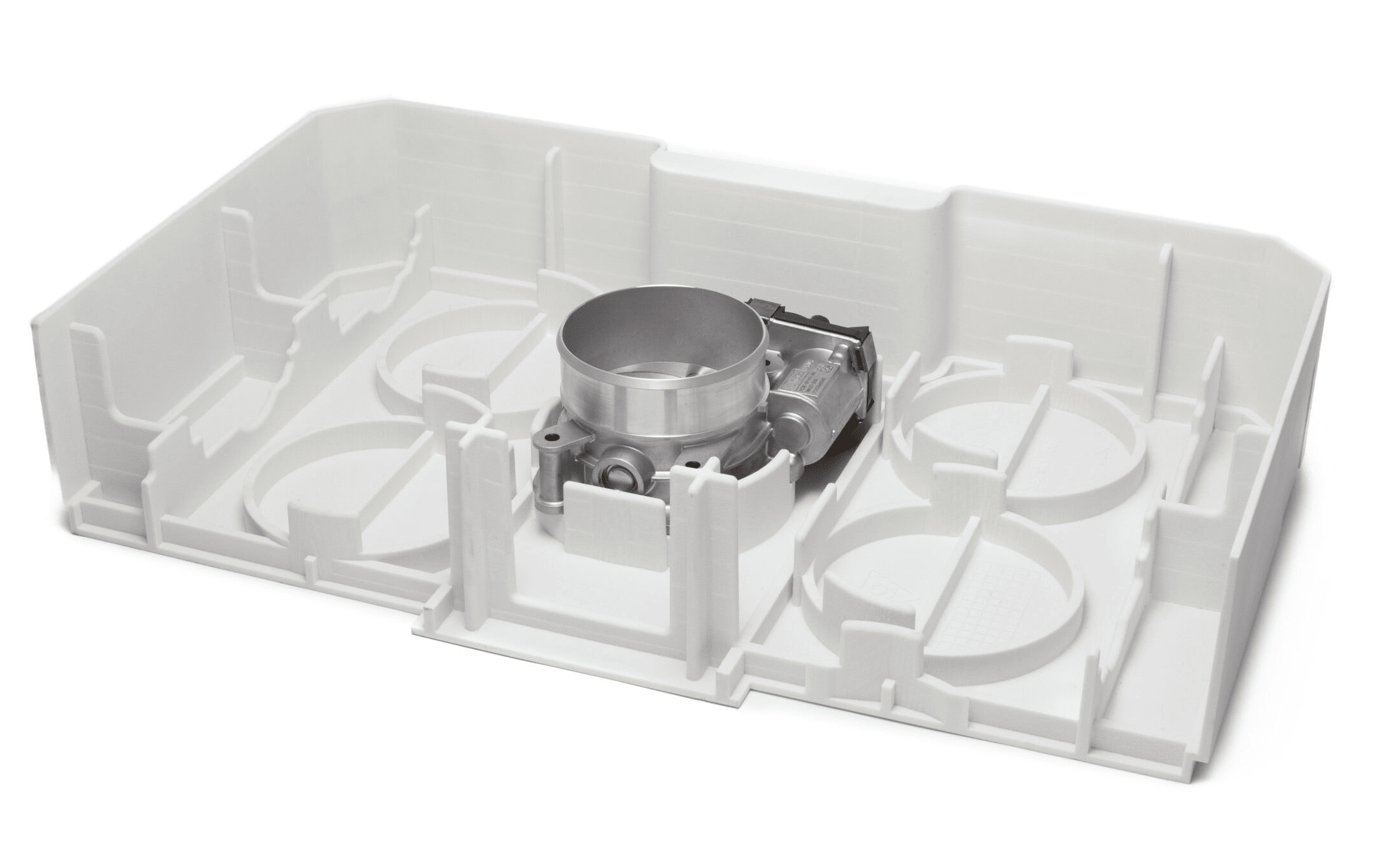

Dunnage Engineering designs and manufactures returnable, reusable trays for the shipping, handling, and/or processing of parts or products for a variety of applications. These trays are specially engineered to protect the parts during shipment and can also be utilized during the manufacturing process.

Capabilities

- We can design trays from part CAD data or actual parts

- We prototype trays using 3D printing or machined model board

- In house large size tray injection molding capacity

- We can mold in steel pins or plates for special applications

- We can include abrasion resistant nests, lids or other components

- We can provide complete unit loads including plastic pallet and lid